Core bits are attached to the foremost part of the core barrels to be used in direct drilling of the ground, and play the most important role among the equipment that are used in drilling. There are many types of bits classified and used according to the purpose of drilling or ground conditions, and the bits are also different in their material, shape, and performance. So, it is economical and highly effective in drilling works to use the proper bits after full understanding of the characteristics of each bit. Diamond core bit is used for the drilling of hard rocks, and metal bit is normally used for the ground or soft rocks. Impregnated core bit is normally used in case core is needed, while non core bit is used if core is not needed. However the drilling efficiency and economic feasibility increase if core Bit is used while core is not needed.

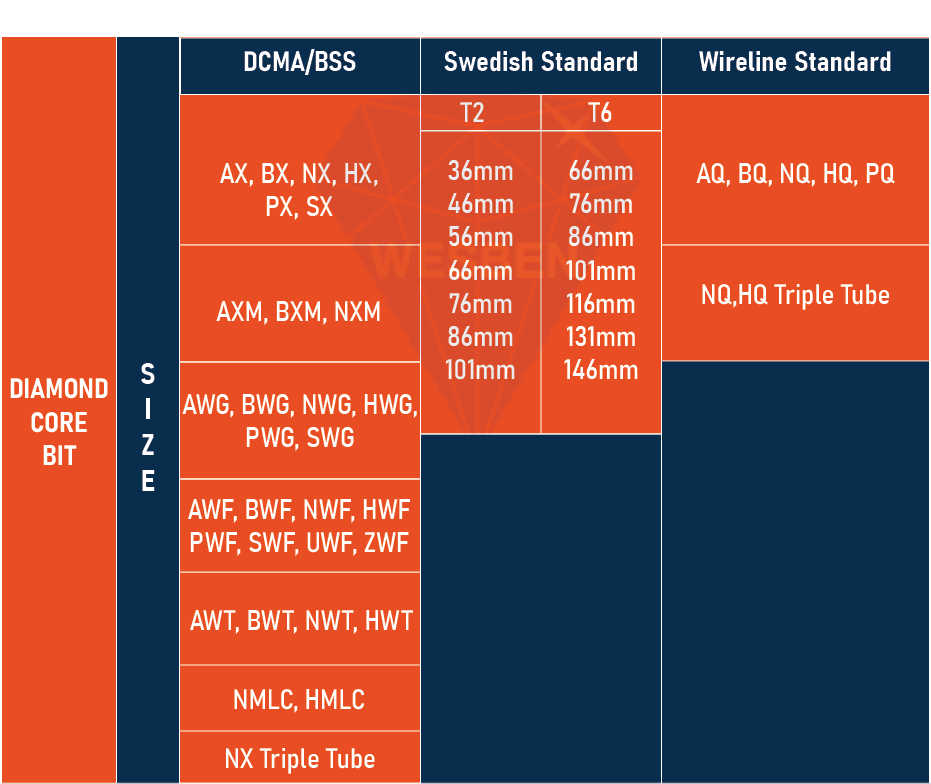

Diamond core bit size and standard specification.

PROFILES

SEMI-ROUND

This is the standard profile which is best suited for most ground conditions.

ROUND

Favoured profile for harder, rough ground conditions with rocks.

STEP

A profile that gives a faster penetration rate, yet is somewhat more delicate particularly in cracked ground. For the most part utilized with wireline core barrel frameworks.

PILOT

A profile that gives great stability, a good penetration rate and recovery. Ideal for soft to medium ground.

ANGLED PILOT

This is a durable profile giving good stability which is ideal very fractured ground.

FACE DISCHARGE

Profile helping in the recovery of core samples in very fragile ground.